US Based Electronics Product Assembly

SourcedGlobally

AssembledLocally

We Can Make Anything

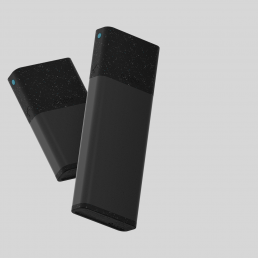

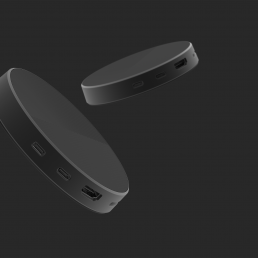

Whatever you need made, we can make it. Our team will manufacture the parts we can, source the parts we can’t and then make and assemble the entire thing here in California. We specialize in mass production, but we have done small runs of high-end products. Our fabrication services are popular for Kickstarter/IndieGoGo prototypes, custom medical products, proof-of-concept prototypes, sample PCB fabrications and more. Have the parts already and need them properly assembled? No problem. Are you a medical professional that needs a device customized? We’ve done that. Have an idea for a large prototype that requires welding and woodwork? We do that! Use the button below to contact us and let’s see how we can work together.

Examples

- Custom Mechanisms / Mechanical Engineering / Mechanical Integration

- Printed Circuit Board Prototypes / Electronic Assemblies

- Build-to-Print (BTP) completed assemblies

- Testing and Validation

- 3D Printed Custom Parts

- Industrial Machinery

- Woodwork / Metalwork

- Sorting Machinery

- Medical Tools

- Custom Displays

- Fixtures

Our Work

Post-Production

Phase 3A:

Quality Control (QC)

Our full-time team in Shenzhen allows us to ensure our client’s the highest standard of QC prior to shipping, saving time and money. Learn more about ANDesign China

Phase 3B:

Assembly

We’re your eyes on the production line. We have close relationships with factories we’ve vetted through years of experience working together. If you’re interested in US based manufacturing or assembly, visit our assembly page.

Phase 3C:

Shipping

Our Project Management team is familiar with the ins and outs of international and domestic shipping. We’ll build a schedule that will take into consideration all the twists and turns that accompany the manufacturing process to ensure your product is where it needs to be when it needs to be there.

Have An Idea?

Do you have a product or idea that needs design or manufacturing? Use the link below to fill out our Product Design Request form and we’ll reach out to you asap to get started on your project.

Manufacturing

Once your design and engineering has been proven through prototypes, and you’ve thoroughly mapped out the production process, you’re ready to move on to manufacturing. From here, there’s no turning back.

Phase 2A:

Tooling

Also known as machine tooling, is the process of acquiring the manufacturing components and machines needed for production. It is manufacturing aids such as cutting tools, fixtures, gauges, molds and patterns of a specialized nature which (unless substantially altered or modified) are solely specific to the production line or the performance of a specific contract or job.

Phase 2B:

Sampling

Once tooling is set up, we use the newly created tool to make production samples. We go through multiple iterations until we arrive at a golden sample. The golden sample sets the standard for future production runs and quality control.

Phase 2C:

Production Run

Our communication with our factory partners is impeccable. All goods are produced by using particular manufacturing procedures, processes or conditions. The most desirable size of a production run required will depend on the consumer demand, production set-up costs and how much, if any, excess inventory to manufacture. If you’re interested in US based manufacturing or assembly, visit our assembly page.

Have An Idea?

Do you have a product or idea that needs design or manufacturing? Use the link below to fill out our Product Design Request form and we’ll reach out to you asap to get started on your project.

Pre-Production

Phase 1A:

Bill of Materials (BOM)

Often referred to as product structure, the Bill Of Materials is a list of raw materials required for product assembly and a comprehensive list of parts, items, assemblies, and sub-assemblies, which can be understood as the recipe and shopping list for creating a final product.

Phase 1B:

Color Material Finish (CMF)

For our products, we create a CMF document that clearly states it’s intended chromatic, tactile, and decorative identity. This helps prevent discrepancies between the output from the design team and the factory in which the product will be manufactured. Our project management and design teams work together to ensure that our client’s products maintain consistent quality, no matter how many hands are involved. We know the details make the product. Learn more about Phase 2 here.

Phase 1C:

Sourcing/Vetting

We’ve instituted set of procedures intended to ensure that a manufactured product and performed service adheres to a defined set of quality criteria or meets the requirements of the client. If it isn’t done under our roof, we’ll make sure all your outsourced materials are inspected accordingly.

Have An Idea?

Do you have a product or idea that needs design or manufacturing? Use the link below to fill out our Product Design Request form and we’ll reach out to you asap to get started on your project.

Prototyping

Phase 4A:

Alpha Prototyping

Phase 4B:

Beta Prototyping

Phase 4C:

Final Prototyping

Have An Idea?

Do you have a product or idea that needs design or manufacturing? Use the link below to fill out our Product Design Request form and we’ll reach out to you asap to get started on your project.

Engineering

Often designers and engineers push and pull between aesthetics and functionality. Our team is made up of industrial designers with a specialty in mechanical engineering so our services have a strong balance between the two. We’re equally capable of making your product work based on aesthetic requirements as we are to make it look great based on functionality requirements. In the most basic terms, sometimes we work on the outside of the product, other times we work on the inside, and most of the time we work on both. In our new product development process, engineering is Step 3 after Concept Design and CAD Modeling. We break engineering down into two main categories: Mechanical Engineering and Electrical Engineering. Below we have a short video we made about our engineering process and a brief written description.

Phase 3A

Mechanical Engineering

Functional products require quality mechanical engineering. Our team of interdisciplinary designers has experience making products work and work well. Whether they’re buttons or switches, we’re determined to create functions that make for useful, intuitive, and enjoyable products. Learn more about what a typical engineering project entails on our engineering services page.

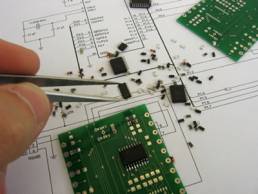

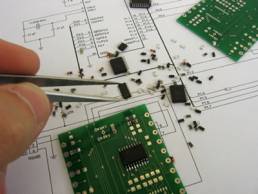

Phase 3B

Electronics Engineering

We have extensive experience working with electrical engineering. From systematic architecture, schematic electrical engineering product design, circuit board prototyping, firmware development and printed circuit board production. We pride ourselves on our electrical projects.

Have An Idea?

Do you have a product or idea that needs design or manufacturing? Use the link below to fill out our Product Design Request form and we’ll reach out to you asap to get started on your project.

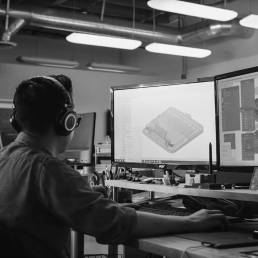

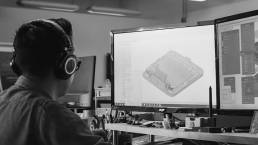

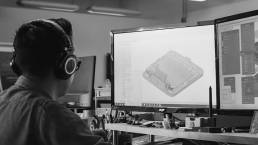

CAD Modeling

Once your Concept Design is done, in order to proceed to Prototyping and Manufacturing, you must digitize your design. This involves 3D modeling using CAD software. A 3D model is one of your most valuable assets in the New Product Development process. It can be used for anything from photorealistic rendering for marketing purposes to prototyping to mass production. It is critical to have an immaculate 3D model and working with our team will ensure that.

Phase 2A:

Computer Aided Design

Phase 2B:

Photo Realistic Rendering

Have An Idea?

Do you have a product or idea that needs design or manufacturing? Use the link below to fill out our Product Design Request form and we’ll reach out to you asap to get started on your project.

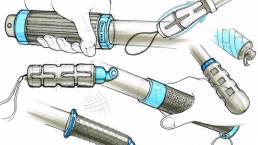

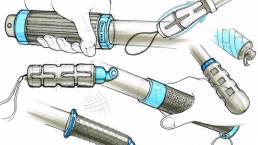

Concept Design

Concept design explores how an idea can be executed. While it focuses on the aesthetic of the product, it also takes into consideration the limitations and requirements of mass production, electronics and mechanical engineering. A fleshed out concept is the roadmap for any great product design. It begins with rough and basic sketches and through a few rounds of revisions it becomes focused and precise.

Phase 1A:

Research, Brainstorm, and Ideation

Every project has a beginning. For our New Product Development (NPD) services we begin by brainstorming in order to reach an in-depth understanding of our client’s requirements and how to achieve them. Once we’re all on the same page, the team then conducts extensive research to devise the most practical and efficient development process. Learn more about our sketching process on our product sketches page.

Phase 1B:

Design Refinement

From here our skilled design team generates a variety of hand drawn concepts that further translate our clients vision. We keep an open dialogue with our clients – updating them every step of the way. This allows us to accommodate any appropriate changes that may occur throughout the product development.

Phase 1C:

Final 2D Drawing

After reviewing these hand drawn design concepts we work with our clients to extract the features that best exhibit their vision. From here we produce a final deliverable 2D rendering. Our clients are then ready to proceed to the next phase of product development, Computer-Aided Design (CAD) Modeling.

Have An Idea?

Do you have a product or idea that needs design or manufacturing? Use the link below to fill out our Product Design Request form and we’ll reach out to you asap to get started on your project.